Our market

& products

Mechanical transmission

Integrated process

Material sobriety

Energetic sobriety

Minimal oxide size (Structure made of agglomerated particles)

Creep resistance (Grain size monitored)

Homogeneity, isotropy

No residual stress

High density (>99%)

Mechanical performances similar to a conventionally made part

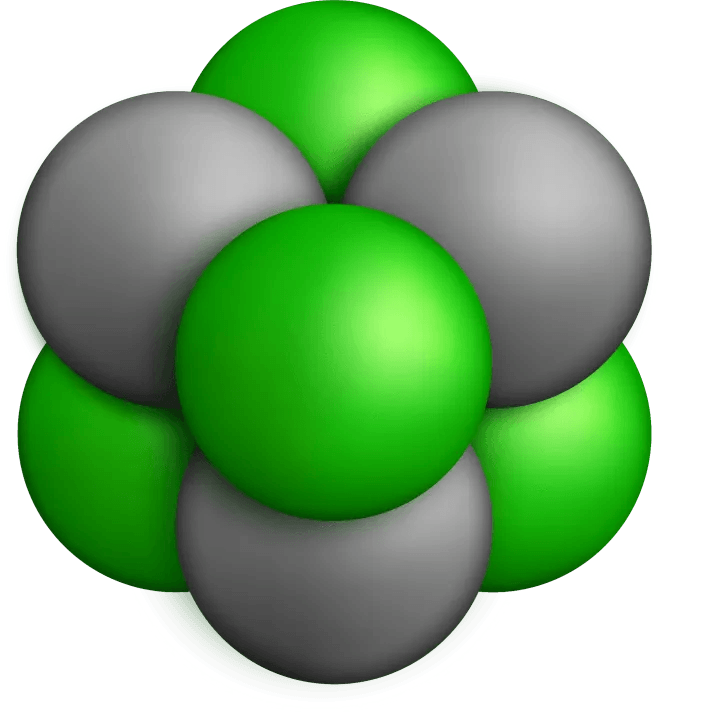

Powder type used : 100Cr6, 16MnCr5, 42CrMo4

Feel free to contact us for another powder type

Magnetic parts

Integrated process

Material sobriety

Energetic sobriety

Freedom of composition → Iron with up to 6% silicium

Homogeneity, isotropy

No residual stress

Excellent permeability & coercive force

High density (> 99%)

Powder type used : Fe 99%; Fe-Si (up to 6%)

Feel free to contact us for another powder type

Wearing part

Integrated process

Material sobriety

Energetic sobriety

Good weldability

Freedom of composition

Homogeneity, isotropy

No residual stress

Mechanical performances similar to a conventionally made part

High density (>99%)

Powder type used : Tool steel

Feel free to contact us for another powder type

Stainless steel fitting

Integrated process

Material sobriety

Energetic sobriety

Good weldability

No residual stress

Homogeneity, isotropy

High density (>99%)

Corrosion behavior comparable to that of a conventional stainless steel part

Powder type used : 316L, 304L, 309L

Feel free to contact us for another powder type

Titanium

Integrated process

Material sobriety

Energetic sobriety

Forged products with a 1/10mm precision

Homogeneity, isotropy

Adapted structure depending on the intended use of the part (knowledge of the α and β phases)

Powder type used : Titanium (Grade 2), Titanium alloy (TA6V - Grade 5)

Feel free to contact us for another powder type